Understanding Reaming in Precision Machining

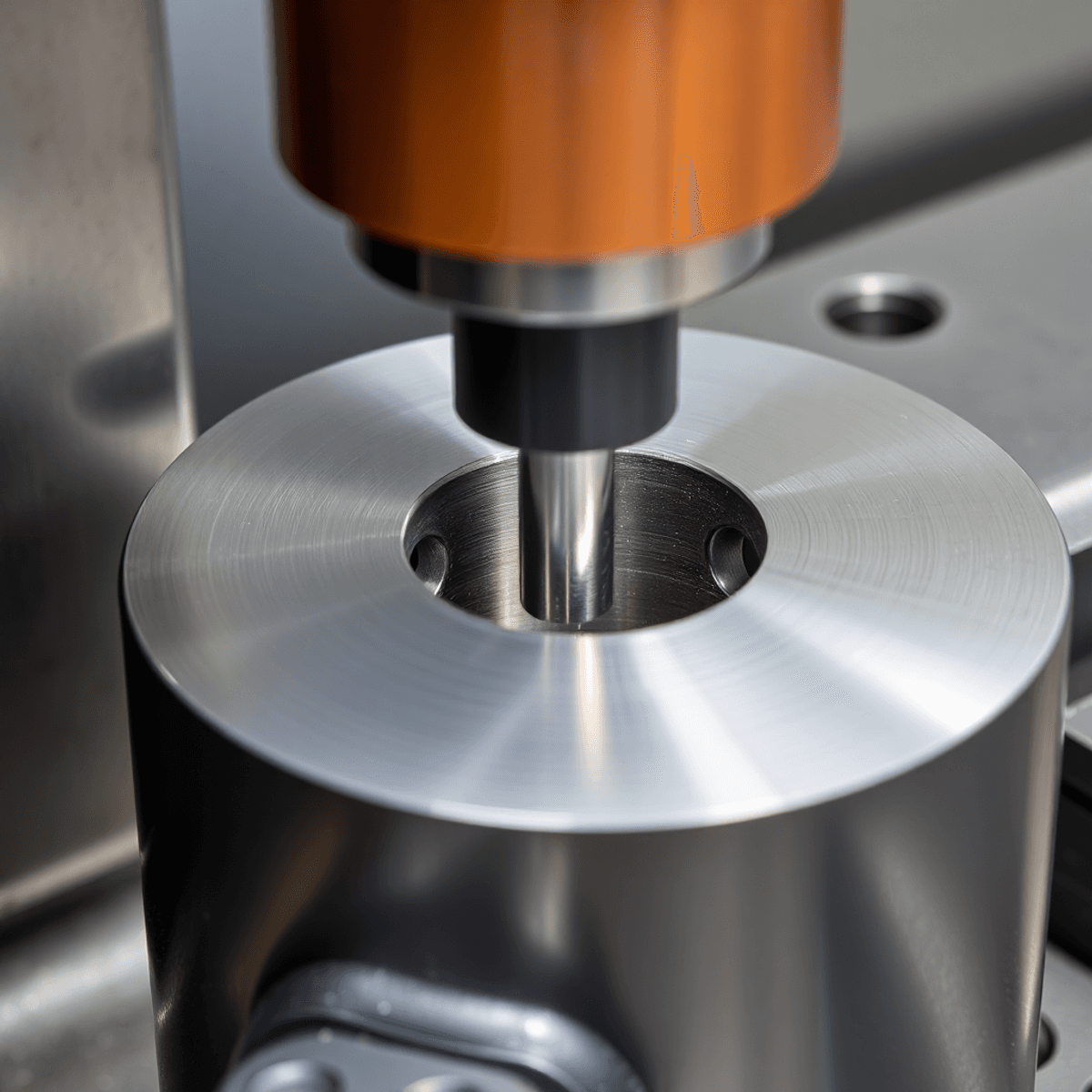

Reaming is an important finishing operation in precision machining. It is used to improve and perfect existing holes in metal workpieces. This specialized process uses a cutting tool called a reamer to achieve exceptional dimensional accuracy and superior surface quality.

Objectives of Reaming

The main goals of reaming are:

- Creating precise hole diameters with tolerances as tight as ±0.0002 inches

- Improving surface finish quality to 10-25 microinches Ra

- Ensuring consistent hole roundness and straightness

- Removing minor imperfections from previous drilling operations

How Reaming Works

A reamer has multiple cutting edges, which allows it to remove small amounts of material from the inside walls of a hole. This careful process of removing material results in holes that meet strict engineering specifications required in high-precision applications.

When to Use Reaming

Reaming is particularly useful in the following situations:

- Manufacturing components that require exact fitting

- Producing parts for aerospace and automotive industries

- Creating medical devices with precise specifications

- Developing oil and gas equipment components

Advantages of Reaming over Drilling

The reaming process offers significant benefits compared to drilling alone. While drilling creates the initial hole, reaming refines it to achieve the exact dimensions and smooth surface finish needed for critical applications. This combination of drilling followed by reaming ensures your machined parts meet the most demanding precision requirements.

Understanding the Reaming Process

Reaming is a precise machining operation used to enlarge and refine existing holes. It involves using a specialized cutting tool called a reamer, which is designed to remove material and create accurate dimensions. The reaming process follows a systematic approach to achieve optimal results in precision hole-making:

Steps Involved in the Reaming Process

- Pre-drilling: Create an initial hole approximately 0.2-0.4mm smaller than the desired final diameter

- Tool Setup: Mount the reamer securely in the machine spindle, ensuring perfect alignment

- Workpiece Positioning: Secure the workpiece firmly to prevent movement during cutting

- Speed Selection: Set spindle speed to 1/3 to 1/2 of the drilling speed

- Feed Rate Adjustment: Maintain consistent feed rate throughout the operation

Machine Setup Options for Reaming

- Drill Press: Ideal for basic reaming tasks with manual feed control

- Milling Machine: Offers improved precision and power feed capabilities

- CNC Machine: Provides automated control and repeatability for complex operations

Critical Parameters for Successful Reaming

- Cutting speed: 10-30% of drilling speed for most materials

- Feed rate: 0.1-0.5mm per revolution

- Coolant flow: Direct to cutting edge for heat dissipation

To ensure optimal results, it’s crucial to understand CNC machining parameters as they play a significant role in the reaming process.

Lubrication Requirements Based on Material

- Steel: Soluble oil or synthetic coolant

- Aluminum: Kerosene or specialized aluminum cutting fluid

- Cast Iron: Dry cutting or minimal lubrication

The reaming process demands strict attention to cutting parameters and proper tool selection. Each material requires specific speed and feed combinations to achieve optimal dimensional accuracy and surface finish. It’s also essential to be aware of potential issues that may arise during this process, such as those related to end mill usage, which can be addressed by referring to an essential guide on troubleshooting common end mill issues.

Types of Reamers: A Comprehensive Guide

Reamers come in diverse designs to meet specific machining requirements. Here’s a detailed look at the main categories:

1. Hand Reamers

- Straight Flute: Features straight cutting edges for general-purpose work, such as those found in carbide straight flute reamers.

- Spiral Flute: Designed with helical flutes for smoother cutting action.

- Adjustable: Allows size modifications through expandable blades

- Shell: Used for large-diameter holes and bearing seats

2. Machine Reamers

- Chucking: Straight-shank design for machine tool holders

- Taper-Shank: Self-centering capability for precise alignment

- Expansion: Adjustable diameter for versatile applications

- Carbide-Tipped: Enhanced durability for tough materials

3. Specialized Types

- Tapered: Creates precise conical holes

- Rose: Left-hand spiral for blind holes

- Gun: Long-length design for deep holes

- Floating: Self-aligning for improved hole accuracy

Each reamer type serves specific functions based on:

- Material requirements

- Hole specifications

- Production volume

- Surface finish needs

- Machine setup constraints

The selection of the appropriate reamer depends on factors like workpiece material, hole depth, required accuracy, and production efficiency requirements. For instance, a DrillMeister can be used to achieve higher production efficiency while maintaining the required accuracy in certain applications.

Specialized Reamer Types for Specific Applications

Specific machining challenges require specialized reamer designs to achieve optimal results. Here’s a detailed look at purpose-built reamers for demanding applications:

1. Carbide-Tipped Reamers

These reamers are built for high-temperature resistance, making them ideal for working with hardened steels and abrasive materials. Their extended tool life in challenging conditions and precision cutting edges ensure accuracy in every job.

2. Shell Reamers

Designed for large-diameter holes, shell reamers feature replaceable cutting edges that help reduce costs. They are perfect for creating bearing seats and housing bores while providing enhanced stability during the machining process.

3. Floating Reamers

With self-aligning capabilities, floating reamers can compensate for minor misalignments and reduce hole distortion. This makes them an excellent choice for automated production lines where precision is key.

4. Expansion Reamers

Expansion reamers offer an adjustable cutting diameter, making them a cost-effective solution for varying hole sizes. Their micro-adjustment capability also makes them suitable for prototype work where exact measurements are crucial.

5. Diamond-Coated Reamers

Engineered specifically for non-ferrous materials, diamond-coated reamers provide superior surface finish capabilities and exceptional wear resistance. They are particularly beneficial when working with composite materials that require a delicate touch.

These specialized tools address specific manufacturing requirements across industries. The selection of the appropriate reamer type depends on factors like material properties, production volume, and precision requirements. Each design offers unique advantages for particular applications, from aerospace components to medical devices.What Is Reaming

Exploring Different Types of Hand Reamers

Hand reamers are important tools used for manually finishing holes with precision. They are versatile tools that come in three main types, each designed for specific uses and finishing requirements.

1. Straight Flute Hand Reamers

Straight flute hand reamers have flutes that run parallel along the length of the tool. Here are their key features:

- Provide excellent stability during operation

- Ideal for through-holes in softer materials

- Create precise, straight-walled holes with minimal taper

2. Spiral Flute Hand Reamers

Spiral flute hand reamers have helical cutting edges. Here are their key features:

- Excellent chip evacuation capabilities

- Reduce cutting pressure during operation

- Perfect for blind holes where chip removal is crucial

- Create smoother surface finishes than straight flute options

3. Tapered Hand Reamers

Tapered hand reamers gradually increase in diameter from tip to shank. Here are their key features:

- Used for creating conical or tapered holes

- Common in pipe fitting and plumbing applications

- Available in standard taper ratios

- Essential for matching tapered pins and connections

Each type of hand reamer requires specific operating techniques:

- Straight flute reamers need steady, consistent pressure.

- Spiral flute versions benefit from slightly faster rotation speeds.

- Tapered reamers demand careful depth control to achieve the desired taper angle.

The choice between these hand reamer types depends on:

- Material characteristics

- Hole configuration (blind vs. through)

- Required surface finish

- Dimensional accuracy needs

- Production volume requirements

Drilling vs. Reaming: Understanding the Differences

Drilling and reaming serve distinct purposes in hole-making operations, each with unique characteristics and applications.

Drilling:

- Creates initial holes in solid material

- Removes large amounts of material quickly

- Achieves tolerances of ±0.005 inches

- Operates at higher speeds

- Produces rougher surface finishes

- Uses two cutting edges

Reaming:

- Refines existing holes

- Removes minimal material (0.004-0.015 inches)

- Achieves tolerances up to ±0.0002 inches

- Operates at lower speeds

- Creates smoother surface finishes

- Uses multiple cutting edges (4-8 flutes)

The cutting action between these operations differs significantly. Drills use a aggressive point angle to penetrate material, creating chips through a splitting action. Reamers employ straight or helical flutes that shear material in thin layers, resulting in better surface quality.

Hole accuracy also varies between these processes. A drilled hole might deviate from true position due to drill wandering or flexing. Reaming follows the existing hole path, improving straightness and roundness while maintaining centerline position.

The choice between drilling and reaming depends on application requirements. Critical applications like engine components or precision instruments often need both operations – drilling for initial hole creation, followed by reaming for dimensional accuracy and surface quality.

Various Approaches to Achieve Precise Hole Sizing Through Reaming Operations

Achieving precise hole sizing through reaming requires specific techniques and approaches. Here are the primary methods used in professional machining:

1. Progressive Reaming

- Start with a smaller reamer size

- Gradually increase reamer diameter

- Ideal for tight tolerances below ±0.001 inches

2. Single-Pass Reaming

- Uses one reamer of final desired size

- Suitable for standard tolerances

- Faster operation time

3. Floating Holder Method

- Compensates for minor misalignments

- Reduces bell-mouthing

- Improves hole straightness

4. Step Reaming

- Multiple cutting edges of increasing diameter

- Combines roughing and finishing in one tool

- Reduces operation time

5. Back Reaming

- Reaming from bottom to top

- Prevents chip accumulation

- Ideal for blind holes

6. Combination Approach

- Uses drill-reamer tools

- Combines drilling and reaming operations

- Reduces tool changes

Each method requires specific cutting parameters:

- Speed: 1/3 to 1/2 of drilling speed

- Feed rate: 0.001-0.003 inches per revolution

- Coolant flow: Continuous during operation

The choice of approach depends on:

- Material properties

- Required tolerance

- Production volume

- Available equipment

It’s also crucial to be aware of potential pitfalls in the process, which is where understanding how to avoid common CNC machining defects and improve part quality can be beneficial.

Industries That Benefit From Precision Holes: A Look At The Uses And Advantages Of Reaming

Precision holes created through reaming operations play a vital role across multiple industries:

1. Aerospace Industry

Reaming is crucial in the aerospace sector for ensuring the precise fit and functionality of various components. Some key applications include:

- Engine component manufacturing

- Landing gear assemblies

- Structural airframe components requiring precise fits

- Hydraulic system components

2. Automotive Manufacturing

In automotive production, reaming is employed to achieve accurate hole sizes and finishes in critical parts. Notable uses encompass:

- Engine block assembly holes

- Transmission components

- Brake system components

- Steering mechanism parts

3. Medical Device Production

The medical device industry relies on reaming to create intricate features and maintain tight tolerances in its products. Significant applications involve:

- Surgical instrument manufacturing

- Implant components

- Medical device housings

- Precision alignment pins

4. Oil and Gas Equipment

Reaming plays a vital role in the oil and gas sector by ensuring proper functioning of various equipment. Key areas where it is utilized include:

- Valve bodies

- Pump components

- Drilling equipment

- Flow control devices

5. Precision Manufacturing

In precision manufacturing, reaming is employed to achieve exact dimensions and surface finishes in critical parts. Some key applications include:

- Bearing housings

- Gear production

- Mold making

- Fixture components

Each industry utilizes specific reamer types to meet their unique requirements. The aerospace industry often employs carbide-tipped reamers for tough alloys, while medical device manufacturers use specialized coated reamers for stainless steel components. The automotive sector benefits from high-speed steel reamers for mass production, and oil and gas equipment makers rely on heavy-duty reamers for large-diameter holes in tough materials.

These industries demand tight tolerances, superior surface finishes, and consistent hole quality – characteristics that reaming operations deliver effectively. The ability to maintain precise dimensions across multiple components ensures proper assembly, optimal performance, and extended service life of manufactured parts.

Best Practices for Effective Reaming in Precision Machining

Achieving optimal results in reaming operations requires strict adherence to specific technical parameters and practices:

Speed and Feed Control

- Maintain slower cutting speeds compared to drilling (typically 1/2 to 2/3 of drilling speed)

- Use consistent feed rates between 0.001 to 0.003 inches per revolution

- Avoid speed fluctuations during the operation

Pre-Operation Setup

- Select hole size 0.004 to 0.012 inches smaller than final dimension

- Ensure proper alignment of the reamer with the pre-drilled hole

- Check tool holder runout before starting

Cooling and Lubrication

- Apply sufficient cutting fluid throughout the operation

- Use sulfur-based cutting oils for steel

- Select water-soluble coolants for aluminum

Tool Management

- Inspect cutting edges regularly for wear

- Replace reamers at the first signs of degradation

- Store tools in protective sleeves to prevent damage

Process Controls

- Never reverse the reamer while in the hole

- Maintain continuous forward motion through the cut

- Remove chips regularly to prevent buildup

Quality Verification

- Check hole dimensions with precision gauges

- Measure surface finish quality

- Document results for process consistency

These practices help achieve hole tolerances within ±0.0002 inches and surface finishes of 16-32 microinches Ra.

Conclusion

Reamers are essential tools in precision machining, providing the accuracy and surface finish required by modern manufacturing. They are irreplaceable in industries such as aerospace and medical device manufacturing, where tight tolerances and superior hole quality are crucial.

The success of reaming operations relies on:

- Proper tool selection

- Precise speed and feed control

- Appropriate cutting parameters

- Regular tool maintenance

By understanding reaming techniques, choosing the right reamer type, and following best practices, machinists can consistently produce high-quality holes. This knowledge turns difficult precision requirements into achievable manufacturing goals, making reamers a must-have in every machinist’s toolbox.

FAQs (Frequently Asked Questions)

What is reaming and why is it important in precision machining?

Reaming is a machining process that involves using a reamer tool to finish holes to precise dimensions and improve surface finishes. It is crucial in precision machining for achieving accurate hole sizes and smooth internal surfaces, which are essential for proper assembly and function of mechanical components.

How is the reaming process performed and what factors affect its success?

Reaming is typically performed by rotating a reamer tool within a pre-drilled hole using machines like drill presses, milling machines, or CNC equipment. Key factors influencing successful reaming include appropriate speed, feed rate, and lubrication, all of which ensure dimensional accuracy and optimal surface finish.

What are the different types of reamers used in machining?

Various types of reamers include hand reamers (such as straight flute, spiral flute, and tapered) and machine reamers. Specialized types like carbide-tipped reamers are designed for hard or abrasive materials. Each type serves specific applications depending on the material and precision requirements.

How do drilling and reaming differ in machining operations?

Drilling creates initial holes by cutting through material, often leaving rough surfaces and less precise dimensions. Reaming follows drilling to refine these holes, improving dimensional accuracy and surface finish. Thus, drilling forms the basic hole while reaming perfects it for precision applications.

What industries benefit from precision holes achieved through reaming?

Industries such as aerospace, automotive, manufacturing, and tooling greatly benefit from precision holes created by reaming. Accurate hole sizing and superior surface finishes ensure reliable assembly, enhanced performance, and longer component life across these sectors.

What are best practices for effective reaming in precision machining?

Effective reaming requires selecting the correct type of reamer for the application, maintaining proper feed rates and speeds, using adequate lubrication to reduce tool wear, and ensuring machine setups are precise. Adhering to these practices results in accurate hole dimensions and high-quality surface finishes.

Parameswar Mohanta

I am a NCVT-certified ITI expert (86% score) and a Full-stack Web Developer. As the founder of Info-ITI, I leverage my 6+ years of experience to provide high-quality NIMI-pattern mock tests and career guidance to ITI students nationwide.